No products in the cart.

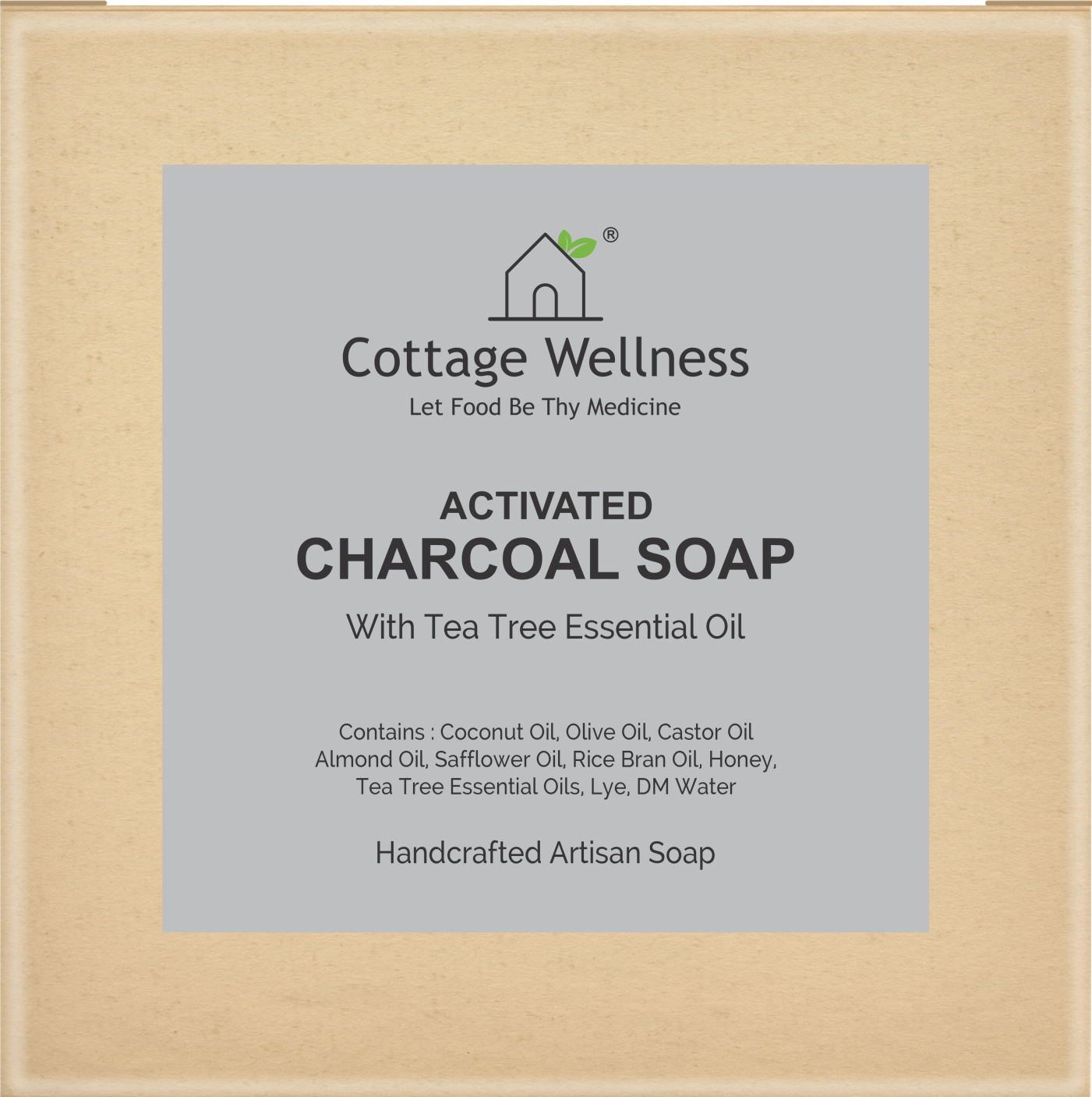

Activated Charcoal Soap – 120 g

₹295.00

Weight: 120 gm

42 in stock

Cottage Wellness Handmade Activated Charcoal Soap is a premium quality soap meticulously crafted with love and care. This soap is enriched with the powerful properties of activated charcoal, which is known for its detoxifying and purifying effects on the skin. Each bar is carefully handmade using the finest natural ingredients, ensuring a luxurious bathing experience. Cottage Wellness Handmade Activated Charcoal Soap effectively cleanses and rejuvenates the skin, leaving it feeling fresh, revitalized, and deeply nourished.

Benefits:

Deep Cleansing: The activated charcoal in this soap acts like a magnet, attracting and removing impurities, toxins, and excess oil from the skin, resulting in a deep and thorough cleanse.

Detoxification: Cottage Wellness Handmade Activated Charcoal Soap helps to detoxify the skin by drawing out impurities and pollutants, leaving it refreshed and revitalized.

Exfoliation: The gentle exfoliating properties of this soap help to remove dead skin cells, unclog pores, and promote a smoother and clearer complexion.

Oil Balancing: This soap is effective in balancing oil production, making it suitable for both oily and combination skin types.

Soothing and Calming: Cottage Wellness Handmade Activated Charcoal Soap soothes and calms the skin, reducing inflammation and irritation, making it beneficial for those with acne-prone or sensitive skin.

Anti-Bacterial: The natural antibacterial properties of activated charcoal help to prevent bacterial growth on the skin, reducing the risk of breakouts and other skin infections.

Improved Skin Texture: Regular use of this soap helps to improve the overall texture and appearance of the skin, leaving it soft, supple, and rejuvenated.

Making Process:

Ingredient Selection: Cottage Wellness Handmade Activated Charcoal Soap is made using carefully selected natural ingredients. This includes activated charcoal, which is derived from organic sources and has undergone a purification process.

Hygiene Maintenance: Maintaining a high level of cleanliness and hygiene is crucial during the soap-making process. The soap-making area and equipment are thoroughly cleaned and sanitized before starting.

Melting and Mixing: The base oils, such as coconut oil and olive oil, are gently melted using controlled heat. Once melted, activated charcoal and other skin-nourishing ingredients, such as shea butter and essential oils, are added and carefully mixed to create a smooth and well-blended mixture.

Blending and Pouring: The ingredients are blended together using precise measurements to ensure a balanced and effective formulation. The soap mixture is then poured into molds, ensuring even distribution and avoiding any air bubbles.

Curing: The soap molds are left undisturbed in a cool and dry area for several weeks to allow the soap to cure and harden naturally. This process is crucial for the soap to achieve its desired texture and longevity.

Cutting and Shaping: Once fully cured, the soap is carefully removed from the molds and cut into individual bars. Each bar is then shaped and smoothed by hand to ensure uniformity and a pleasing aesthetic.

Packaging: The final step involves packaging the soap with care. Each bar is wrapped in eco-friendly materials, preserving its freshness and protecting it from external elements.

Neatness and Hygiene Maintenance While Making Soap:

Clean Work Surface: The soap-making area is thoroughly cleaned and sanitized before starting the process. This ensures a clean and hygienic environment for soap production.

Personal Hygiene: The soap maker maintains strict personal hygiene by washing hands thoroughly, wearing gloves, and tying back hair to prevent any contamination.

Equipment Sanitization: All equipment used in the soap-making process, such as mixing bowls, molds, and utensils, are properly cleaned and sanitized before use to prevent cross-contamination.

Ingredient Handling: The ingredients used in soap making are stored in a clean and dry area to maintain their quality. They are handled with clean hands or sanitized utensils to avoid introducing contaminants.

Proper Ventilation: Adequate ventilation is maintained in the soap-making area to ensure good air circulation and minimize the risk of any airborne contaminants.

Storage and Packaging: The finished soap bars are stored in a clean and dry environment until they are ready for packaging. Packaging materials, such as wrappers or boxes, are also stored in a clean and sanitary manner.

Quality Control: Cottage Wellness maintains strict quality control measures to ensure that each soap bar meets the highest standards of cleanliness, hygiene, and quality. Any soap that does not meet the company’s quality criteria is discarded.

Ongoing Maintenance: Regular cleaning and maintenance of the soap-making equipment and work area are carried out to uphold cleanliness and hygiene standards.

At Cottage Wellness, maintaining neatness and hygiene throughout the soap-making process is a top priority, ensuring that each bar of Cottage Wellness Handmade Activated Charcoal Soap is safe, clean, and of the highest quality.

| Weight | 0.2 kg |

|---|

Be the first to review “Activated Charcoal Soap – 120 g” Cancel reply

Activated Charcoal Soap – 120 g

₹295.00

Reviews

There are no reviews yet.